Ineos

The challenge

At the testing centre of Ineos Brussels, the 8-way autoclave system for testing the catalyst in the polymerisation process of ethylene was run twice a day by one operator – by manually operating the existing SCADA software.

Ineos challenged Pro Control to come up with a solution that allowed the same operator to run the system 8 times a day.

Ineos challenged Pro Control to come up with a solution that allowed the same operator to run the system 8 times a day.

The solution

To run multiple tasks per day, these tasks must be performed in parallel. This means that several operators must work simultaneously.

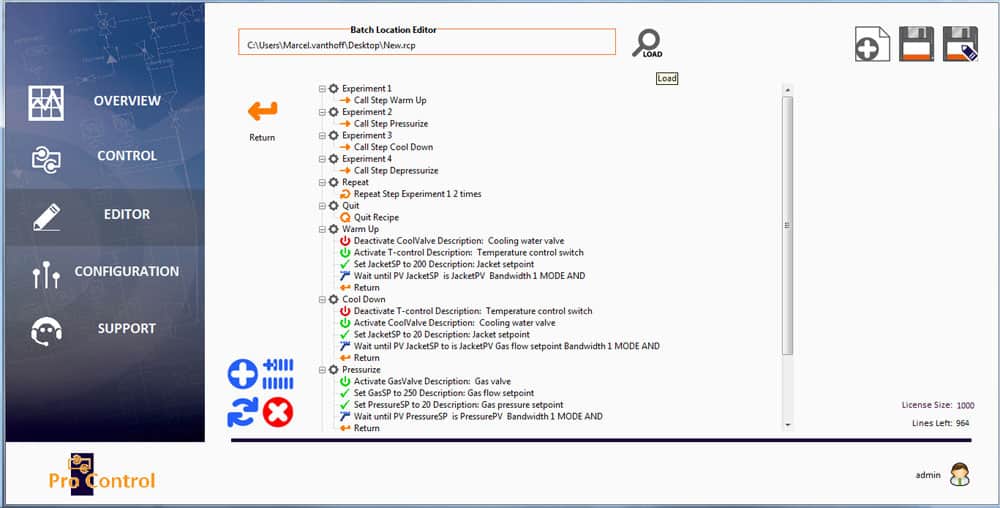

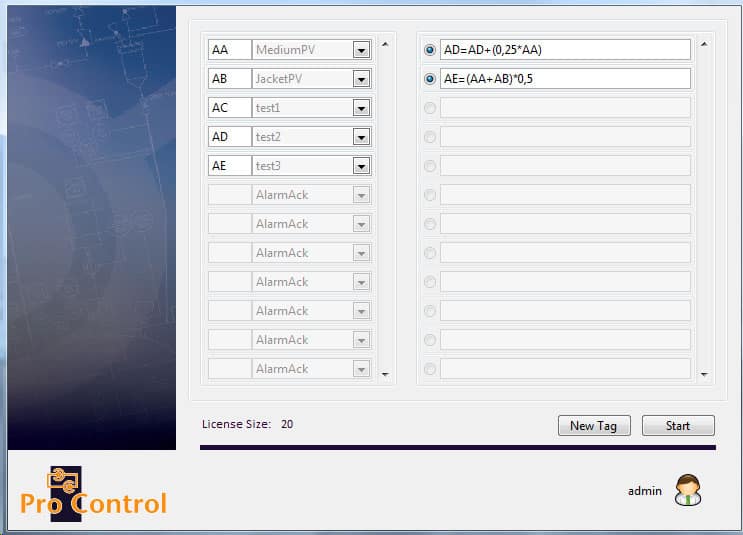

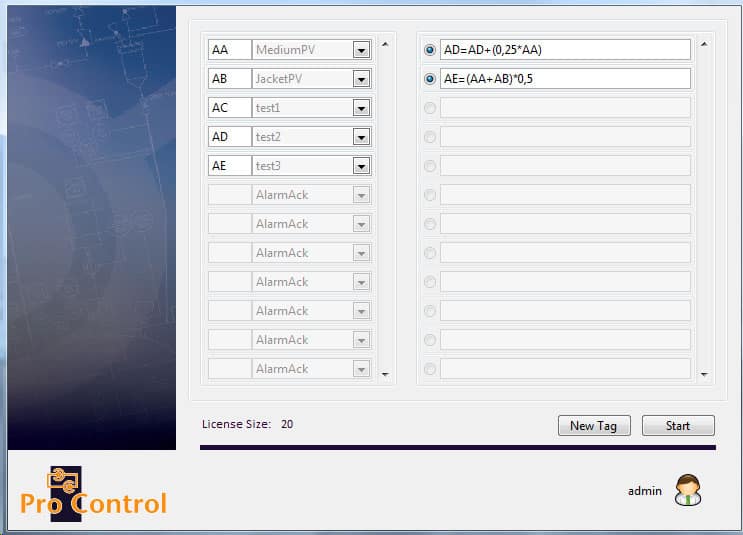

Pro Control already had a software application: Dizanta Compass. Pro Control used this automated operator, which is one of the modules in the Dizanta Suite, to take the SCADA application to a higher level of automation.

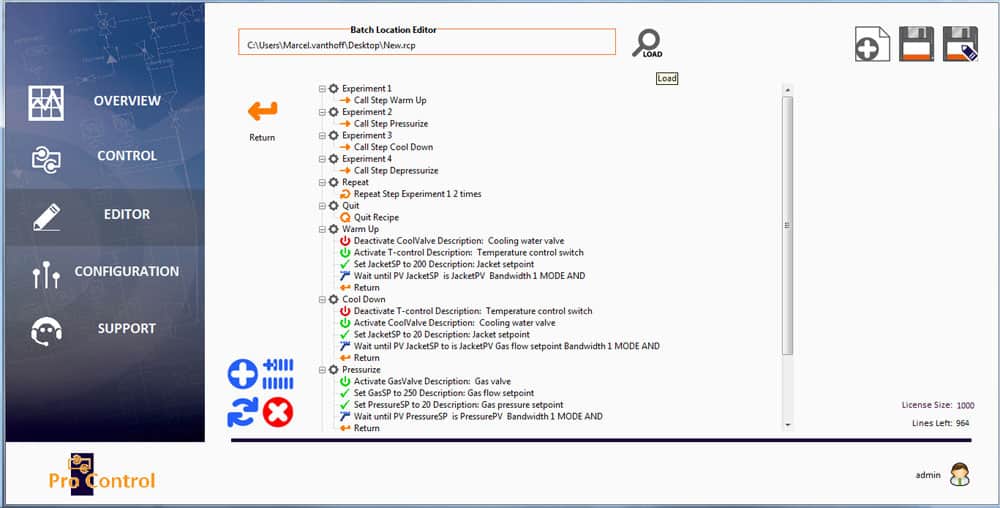

Dizanta Compass can take over the tasks of a human operator using a predefined recipe of all required actions and transitions.

For Ineos Brussels, we now had to make sure that Dizanta Compass could perform several recipes in parallel. That’s why we expanded the module to include parallel recipe execution.

Pro Control already had a software application: Dizanta Compass. Pro Control used this automated operator, which is one of the modules in the Dizanta Suite, to take the SCADA application to a higher level of automation.

Dizanta Compass can take over the tasks of a human operator using a predefined recipe of all required actions and transitions.

For Ineos Brussels, we now had to make sure that Dizanta Compass could perform several recipes in parallel. That’s why we expanded the module to include parallel recipe execution.

The result

Dizanta Compass now runs in the testing centre of Ineos Brussels, in parallel, with a maximum of 8 recipes, which is about 10 tasks a day – so we more than achieved the goal!

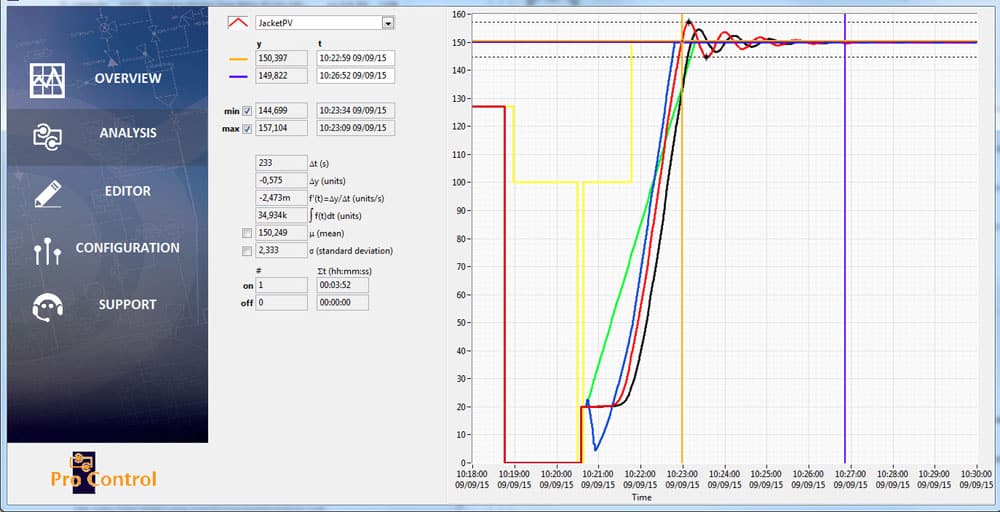

We even went a step further and also installed the Dizanta trending tool with on-the-fly analysis capabilities for pre-selected trends within a specific time span, such as:

• Minimum and maximum value

• Mean value

• Standard deviation

• Integral and derived information

This analysis tool offers useful and rapid information and direct insight into the process. Even Ineos Brussels could not manage without it.

We even went a step further and also installed the Dizanta trending tool with on-the-fly analysis capabilities for pre-selected trends within a specific time span, such as:

• Minimum and maximum value

• Mean value

• Standard deviation

• Integral and derived information

This analysis tool offers useful and rapid information and direct insight into the process. Even Ineos Brussels could not manage without it.

Gallery